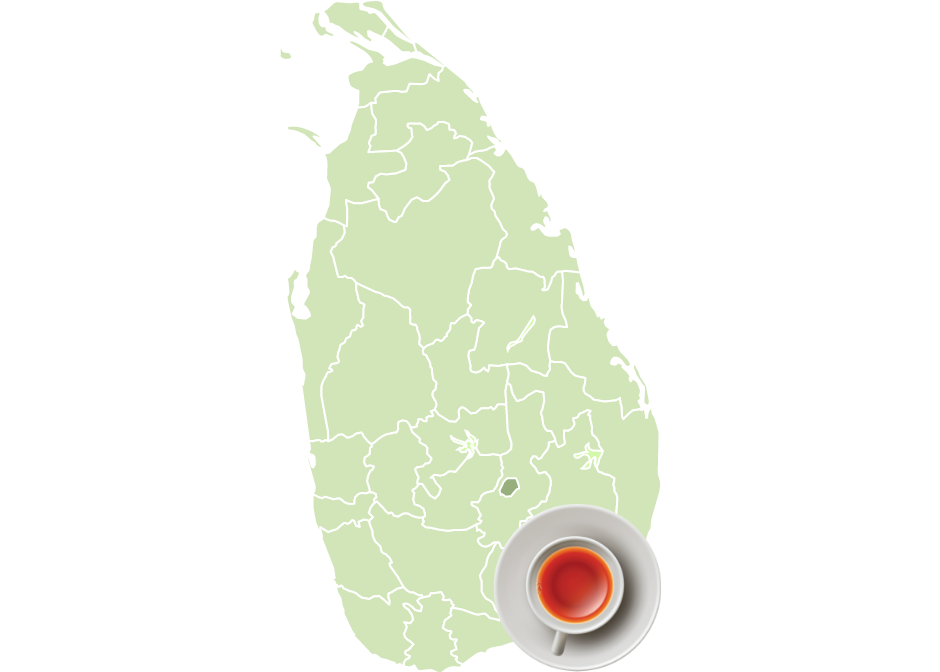

Travel back in time for 200 years along the tea trail, and you will find yourself the most amazing chronicle; The story of Ceylon tea which astonishingly found its’ birth story in Coffee! In the 1870s, Coffee plantations were devastated by a fungal disease. The death of the coffee industry marked the end of an era when most of the plantations on the island were dedicated to producing coffee beans. In 1824 a tea plant was brought to Ceylon by the British from China and was planted in the Royal Botanical Garden in Peradeniya for experimental purposes and since then, tea has only grown in popularity. Today, Ceylon tea has found its’ way in to the hearts and minds of people across the globe!

This agro-climatic district is considered to be the "Golden Valley" of the tea industry because it covers an extensive area from around 3500ft to 5000ft above sea level in the Western slopes of the country. The mountains and the valleys extend from Bogawantalwa and Maskeliya bordering the Adams Peak wilderness to Hatton, Dickoya, Talawakelle and Nanuoya- all up to the Western boundary of Nuwara Eliya. Different climatic conditions present in these areas result in a range of teas from full bodied to light delicate flavour, grown in different valleys.

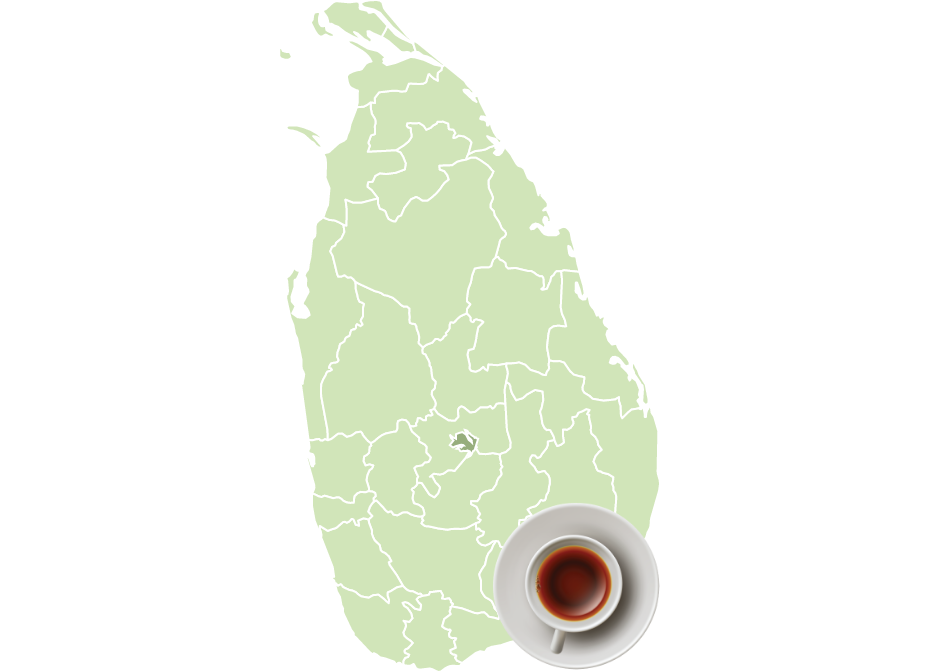

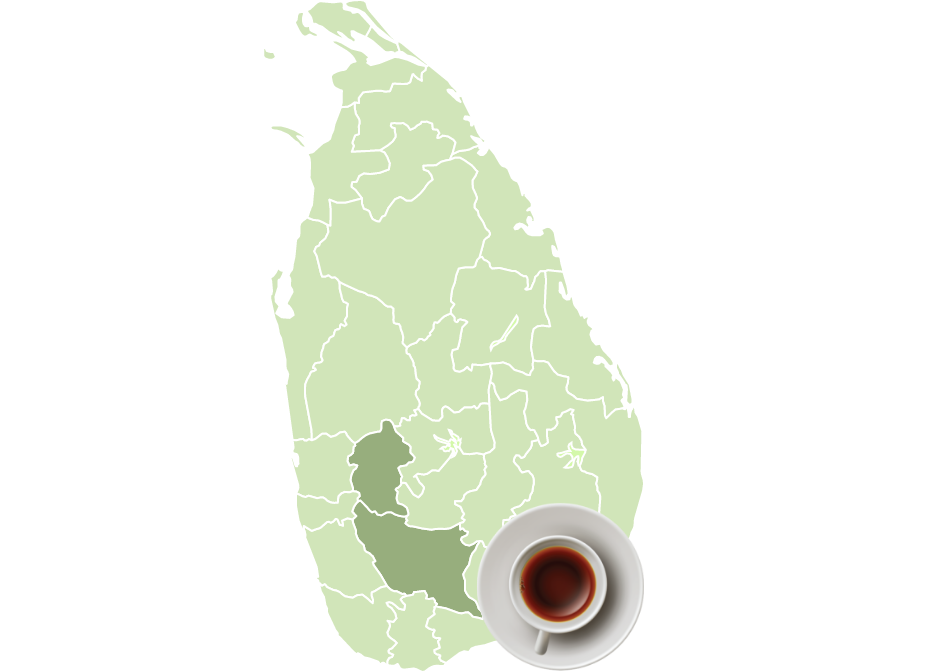

Mid country teas grown on plantations at 2,000 to 4,000 meters above sea level produce a full-bodied tea. Ideal for those who like their tea strong and bursting with flavour. Best served with milk.

With verdant hills and cloud of mist surrounding the region, the cup of tea produced by this region also carries this mystique. Recognized by tea connoisseurs, Nuwara Eliya is what carries the legacy of Ceylon tea. Coming from an elevation of is 6,240 feet, this tea makes for a very smooth cup of tea that can also be iced for a refreshing difference.

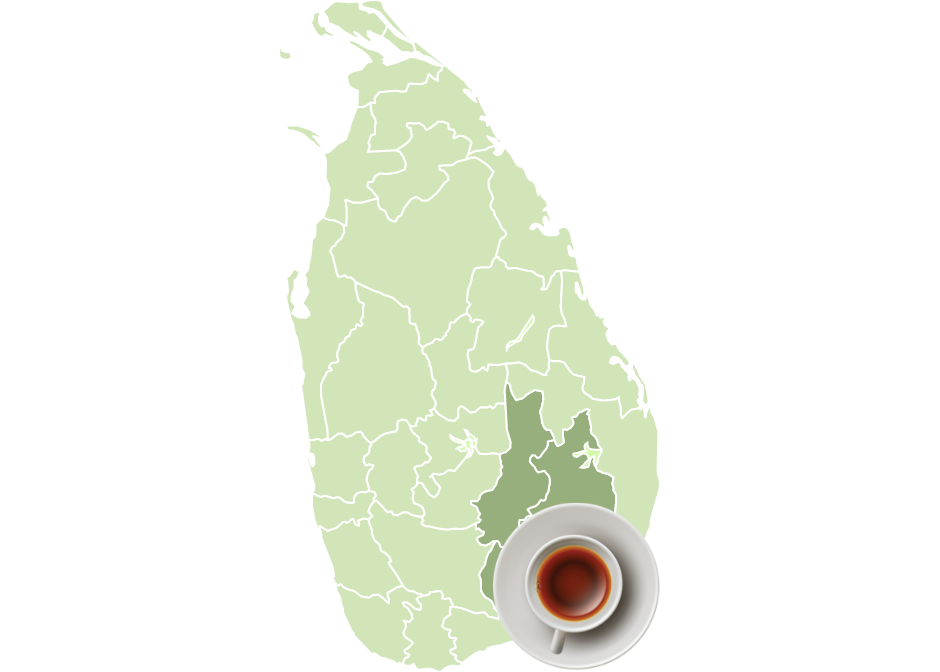

Grown at an elevation between 3,000 to 5,000 feet above the sea level, on the Eastern slopes of Sri Lanka’s central mountains, Uva teas carry a truly unique flavour. These teas are commonly used in many different blends but, with their different characteristics, they can also be enjoyed on their own.

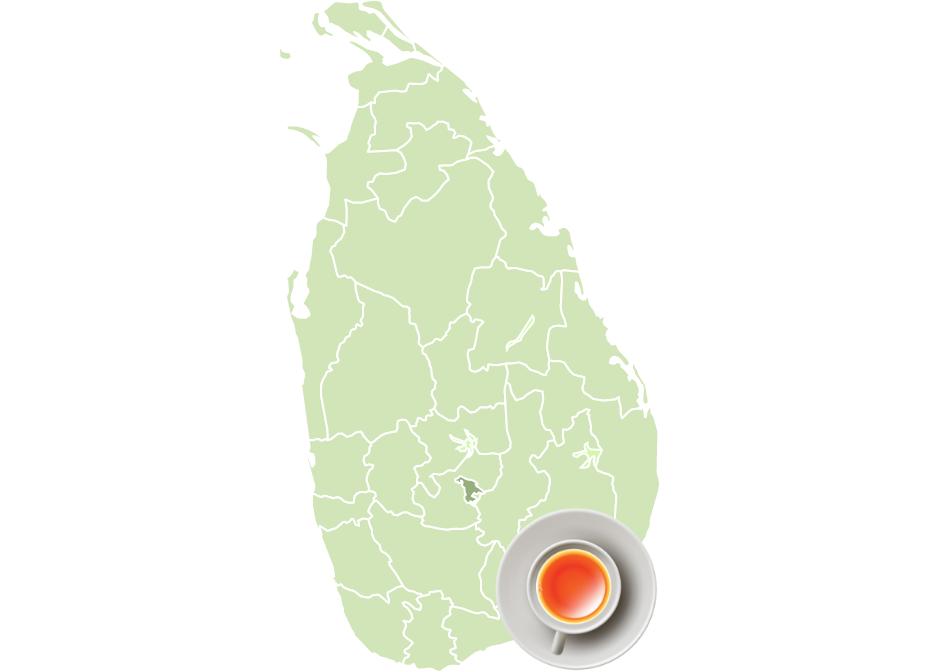

The tea grown on the Uda Pussellawa mountain range experiences two seasons of superior quality. The traditional Eastern season ranges from July to September but the dry, cold condition of the first quarter of the year yield a range of rosy teas. These teas come with subtle character but produce a majestic flavour.

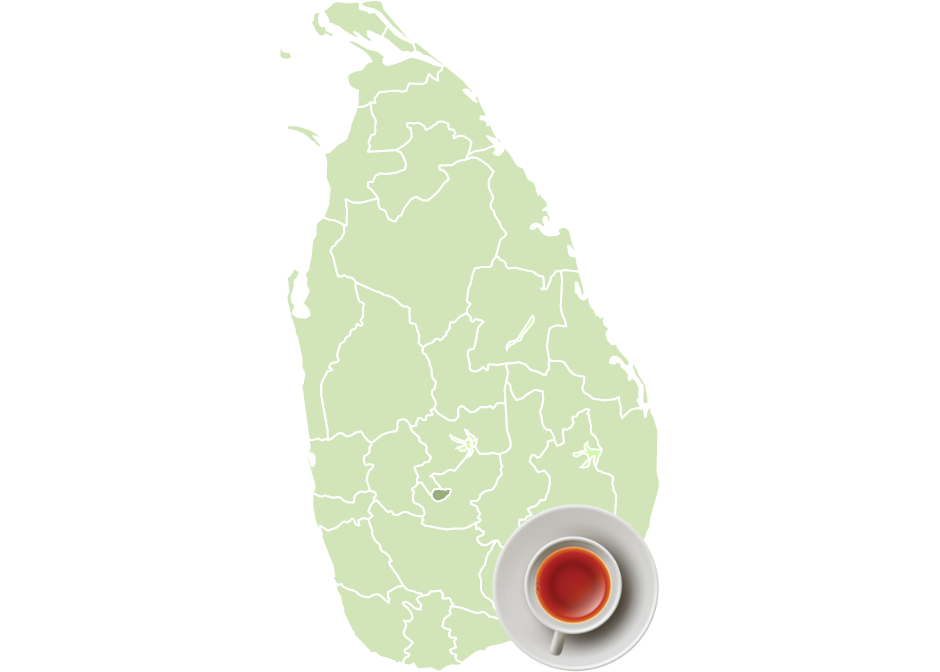

Sabaragamuwa Province, located about 2,500 feet above sea level, is usually referred to as low grown tea and typically known for their stylish leaf appearance and larger particle size. The blackness of the dry leaf is a distinctive feature as it infuses a bold, deep red colour to the brew, lending it a smooth and full-bodied flavour.

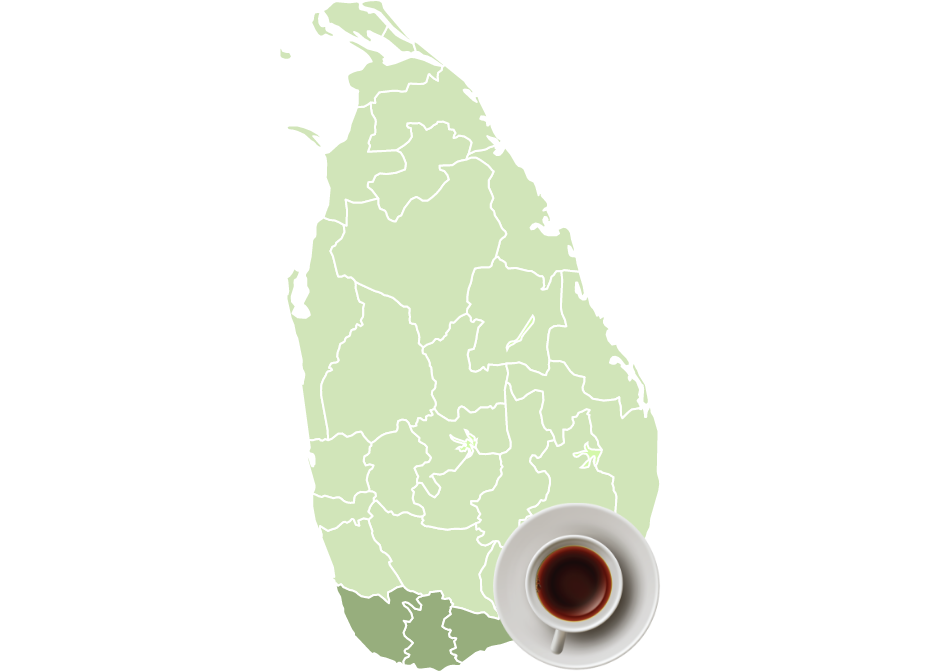

The Southern portion of Sri Lanka, though not traditionally known for its tea growing, does produce exceptional tea. Grown at almost sea level and also 2,000 feet above sea level, the uniqueness of this tea lies in the bold, black brew it creates, with a strong flavour profile. A perfect cup for those who like their tea thick and sweet, with or without milk.

The art is at the heart of this arduous process, which leads to delightful results. The meticulous process of tea manufacturing begins with the plucking of good leaf – two leaves and a bud. Ceylon tea is manufactured predominantly using the orthodox tea manufacturing process that has been preserved for well over a century.

From plucking to finally sorting, grading and tasting, every level of this multi-tiered process is backed by years of experience and specialization, which we at CTM uphold with great care.